Solid vs. Engineered Hardwood Flooring: Understanding the Cost Differences for Chicago Homeowners

Choosing between solid and engineered hardwood flooring involves weighing their distinct advantages and cost structures, impacting your home investment in the Northwest Suburbs of Chicago. Homeowners frequently inquire about the price disparities between solid and engineered hardwood options as they balance initial expenses, long-term value, and suitability for our local climate. This comprehensive guide breaks down the material, installation, and refinishing costs for both types of flooring, offers a direct price comparison, examines their lifespans and return on investment, addresses Chicago’s humidity challenges, and highlights design and sustainability considerations. You’ll also discover how Premier Custom Hardwood Flooring’s expertise provides personalized solutions and complimentary estimates to help you make a confident decision.

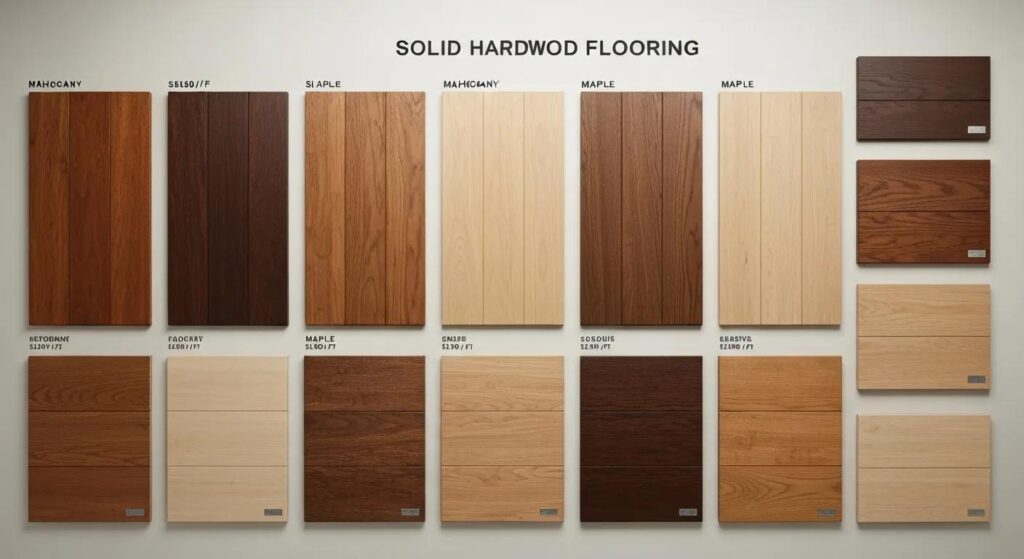

What Exactly Is Solid Hardwood Flooring and How Are Its Costs Structured?

Solid hardwood flooring is meticulously crafted from a single piece of genuine wood, celebrated for its enduring durability, timeless elegance, and the ability to be refinished multiple times.

What Defines Solid Hardwood Flooring?

Solid hardwood flooring is composed of uniform planks milled from a single timber, offering consistent thickness, authentic grain patterns, and the capacity for numerous sanding and refinishing sessions. This construction ensures exceptional stability, a genuine appearance, and a lifespan that can easily surpass 75 years, positioning it as a premier choice for areas with moderate humidity levels.

Building on its classic appeal, engineered hardwood offers an alternative for environments where solid wood might be susceptible to warping, a topic we will explore next.

What Are the Typical Material Costs for Solid Hardwood in the Chicago Area?

In the Northwest Suburbs of Chicago, material prices are influenced by the wood species and its grade. Here’s a representative cost range:

- Oak (Red or White) – $6.50 to $8.50 per square foot

- Maple or Hickory – $7.00 to $9.50 per square foot

- Exotic species (Cherry, Walnut) – $9.00 to $12.00 per square foot

These figures represent typical warehouse pricing through local suppliers and include standard finishes. Opting for premium custom stains or wider planks can add an additional $1.50 to $3.00 per square foot.

The selection of local wood species not only affects cost but also resale appeal, which we will compare with engineered wood in the following section.

What Is the Local Cost for Installing Solid Hardwood Flooring?

Professional installation rates in the Chicago suburbs are influenced by the condition of the subfloor, the complexity of the room, and the chosen installation method:

- Nail-down installation – $4.00 to $6.00 per square foot

- Staple-down installation – $3.50 to $5.50 per square foot

- Glue-down (typically for engineered) – $5.00 to $7.00 per square foot

These labor costs generally encompass moisture testing, the installation of moldings, and site protection measures. Intricate layouts, such as diagonal patterns or borders, may increase labor expenses by 10–15%.

Expert flooring installation is crucial for ensuring long-lasting performance, even when subjected to regional temperature fluctuations.

What Is the Refinishing Potential and Associated Cost for Solid Hardwood Floors?

Solid hardwood floors can be refinished multiple times, effectively restoring their like-new appearance and significantly extending their lifespan:

- Typical refinishing cost – $3.00 to $5.00 per square foot

- Includes sanding, dustless containment, stain application, and protective topcoat

- Recommended interval – every 10–15 years, depending on wear and tear

Refinishing solid hardwood floors up to 5–6 times helps maintain their structural integrity and can offer substantial savings compared to replacement over several decades. Next, we will examine the refinishing options available for engineered hardwood.

How Does Engineered Hardwood Flooring Differ, and What Are Its Price Determinants?

Engineered hardwood features a genuine wood veneer atop a core of layered plywood or HDF, enhancing its resistance to moisture while preserving a natural aesthetic.

What Is Engineered Hardwood Flooring and How Is It Constructed?

Engineered hardwood flooring is constructed with a top layer of real hardwood veneer bonded to multiple cross-grain plywood or high-density fiberboard (HDF) layers. This cross-layered construction minimizes expansion and contraction, providing superior stability in basements, over radiant heating systems, and in environments with high humidity. The thickness of the veneer (wear layer) dictates how many times it can be refinished, while the core material influences its dimensional stability.

This engineered core is better equipped to handle Chicago’s seasonal humidity shifts, a factor we will discuss further in the climate section.

Engineered Wood Flooring - Explained Simply

Engineered wood flooring is constructed with a top layer of real hardwood veneer bonded to multiple cross-grain plywood or high-density fiberboard layers. This cross-layered structure reduces expansion and contraction, delivering enhanced stability in basements, over radiant heat, and in humid climates.

The Engineered Wood Flooring Association, “Engineered Wood Flooring Guide” (2023)

What Are the Average Material Costs for Engineered Hardwood in the Northwest Suburbs?

Material costs for engineered hardwood vary based on the thickness of the wear layer and the wood species:

- 2 mm wear layer – $4.00 to $6.00 per square foot

- 3 mm wear layer – $6.50 to $8.00 per square foot

- 5 mm wear layer (premium) – $8.50 to $11.00 per square foot

Standard oak veneers are typically the most budget-friendly, while exotic veneer options can range up to $12.00 per square foot. Prefinished options often come with durability warranties and UV-cured finishes at no additional labor cost.

The choice of material involves balancing budget, desired durability, and aesthetic preferences, which we will cover in the direct comparison section.

What Is the Cost of Installing Engineered Hardwood in Chicago?

Local installation rates for engineered hardwood reflect the costs associated with floating, glue-down, and nail-down methods:

- Floating installation – $3.00 to $5.00 per square foot

- Glue-down method – $5.50 to $7.00 per square foot

- Nail-down (for thicker planks) – $4.50 to $6.50 per square foot

Essential preparation steps, such as leveling concrete subfloors and installing moisture barriers, are typically included in these rates.

Professional installation is key to minimizing callbacks and preventing finish failures, directly contributing to long-term value.

Can Engineered Hardwood Be Refinished, and What Are the Associated Costs?

The refinishing potential of engineered hardwood depends on the thickness of its veneer:

- 2 mm veneer – generally not refinishable

- 3 mm veneer – refinishable once, at a cost of $4.00 to $6.00 per square foot

- 5 mm veneer – refinishable 2–3 times, at a cost of $5.00 to $7.00 per square foot

The veneer thickness dictates the achievable sanding depth; thicker layers can withstand multiple refinishing cycles but come with a higher initial price. Understanding these limitations is vital for planning replacement versus restoration decisions.

What Are the Direct Cost Comparisons Between Solid and Engineered Hardwood Flooring?

Comparing the material and installation expenses side-by-side provides a clear picture of the budget implications and helps guide informed decisions.

Hardwood Flooring Costs and Installation - A Detailed Look

This study provides an overview of the costs associated with hardwood flooring, including material costs, installation expenses, and refinishing costs. It also compares the costs of solid hardwood and engineered hardwood flooring, highlighting the factors that influence price variations.

National Wood Flooring Association, “Hardwood Flooring 101” (2024)

How Do Material Costs Compare Between Solid and Engineered Hardwood?

Here is a representative cost comparison for common oak species in the Chicago suburbs:

| Flooring Type | Wear Layer or Plank Thickness | Typical Cost per sq ft |

|---|---|---|

| Solid Hardwood | 3/4 in plank | $6.50–$8.50 |

| Engineered Hardwood | 2 mm veneer | $4.00–$6.00 |

| Engineered Hardwood | 3 mm veneer | $6.50–$8.00 |

| Engineered Hardwood | 5 mm veneer | $8.50–$11.00 |

This table illustrates that engineered options often have an entry price that is 20–40% lower than solid wood, with premium engineered planks priced comparably to solid wood options.

These cost differences reflect variations in material requirements and manufacturing complexity.

How Do Installation Costs Differ for Solid vs. Engineered Hardwood?

Local labor costs vary depending on the installation method and the necessary subfloor preparation:

| Installation Method | Solid Hardwood Labor | Engineered Hardwood Labor |

|---|---|---|

| Nail-down | $4.00–$6.00 per sq ft | $4.50–$6.50 per sq ft |

| Staple-down | $3.50–$5.50 per sq ft | N/A |

| Glue-down | $5.00–$7.00 per sq ft | $5.50–$7.00 per sq ft |

| Floating (click) | N/A | $3.00–$5.00 per sq ft |

Floating installations can reduce labor costs by up to 30% but may necessitate the use of transition moldings. Solid wood installations often require more precise nailing techniques and extended acclimation periods.

The choice of installation method impacts the overall project timeline and the final quality of the finish, directly influencing the flooring’s lifespan and return on investment.

What Factors Influence Price Variations in Both Flooring Types?

Several key attributes significantly influence the cost differences between flooring types:

- Wood species and grade

- Plank width and length

- Wear layer thickness (for engineered) or plank thickness (for solid)

- Finish type (pre-finished UV-cured vs. site-applied)

- Installation complexity (layout patterns, molding types)

- Subfloor preparation and moisture mitigation requirements

Custom finishes and wide-plank designs can add $1.00–$3.00 per square foot, while the inclusion of moisture barriers and leveling compounds might add an additional $1.50–$2.50 per square foot.

A thorough understanding of these variables enables homeowners to optimize both their budget and the performance of their flooring.

What Are the Long-Term Value and Return on Investment Differences?

Beyond the initial purchase price, factors such as refinishing potential, expected lifespan, and impact on resale value reveal the true long-term worth of your flooring investment.

How Does Refinishing Affect the Lifespan and Cost Efficiency of Each Flooring Type?

The ability of solid hardwood to be refinished multiple times can extend its usable life by decades; each refinishing session, costing $3.00–$5.00 per square foot, restores its appearance for a fraction of the cost of replacement. Engineered hardwood with a 3 mm wear layer can be refinished once, delaying the need for complete replacement but limiting long-term cost savings. Floors with thicker wear layers (5 mm) can accommodate two to three refinishing cycles at $5.00–$7.00 per square foot, though eventual replacement will still be necessary sooner than with solid wood.

The ongoing cost of refinishing must be weighed against the eventual cost of replacement, guiding a comprehensive lifecycle cost analysis.

What Is the Expected Lifespan of Solid vs. Engineered Hardwood Flooring?

Typical service life estimates include:

- Solid hardwood – 75 to 100+ years with appropriate periodic refinishing

- Engineered hardwood – 20 to 50 years, depending on veneer thickness and finish durability

How Does Flooring Choice Impact Home Resale Value in Chicago?

Hardwood flooring consistently ranks among the home improvement projects offering the highest return on investment. Solid hardwood can recoup 70–80% of its material and installation costs at resale, largely due to its perceived luxury and exceptional durability. Engineered hardwood typically yields a 60–70% recoupment, offering a balance of affordability and sustainability. Local market trends indicate that warm oak tones and wide planks are particularly desirable, commanding premium offers and directly linking design choices to property valuation.

The impact on resale value is influenced by the species selected, plank width, and the quality of the finish, all tailored to regional buyer preferences.

How Does Chicago’s Climate Affect the Cost and Suitability of Hardwood Flooring?

Chicago’s dramatic seasonal humidity fluctuations and harsh sub-zero winters present unique moisture and stability challenges for all types of wood flooring.

Why Is Moisture Resistance Important for Hardwood Floors in Chicago?

The relative humidity in Chicago can range from below 20% in the winter to over 60% in the summer. Without effective moisture control, wood flooring exposed to these extremes can experience cupping, gapping, or buckling. Engineered hardwood’s cross-layered core construction significantly resists dimensional changes, thereby reducing the likelihood of warranty claims and installation callbacks, especially in high-humidity areas like basements or kitchens.

Maintaining consistent moisture levels through HVAC regulation and proper installation techniques is crucial for enhancing the longevity of your floors and preserving the integrity of their finish.

Which Flooring Type Performs Better in Humid and Seasonal Conditions?

Engineered hardwood generally maintains better plank stability and limits seasonal expansion due to its multi-ply construction, making it a more suitable choice for basements and sunrooms. Solid hardwood performs optimally in main living areas with consistent climate control but requires careful acclimation and moisture barriers when installed in transitional spaces.

Adhering to proper acclimation protocols before installation can mitigate most risks associated with seasonal performance for both flooring types.

How Do Installation Methods Mitigate Climate-Related Issues?

Specialized installation techniques are employed to protect against moisture-related damage:

- Installation of moisture-vapor barriers beneath concrete or slab subfloors

- Floating installations that incorporate perimeter expansion gaps

- Application of site-specific sealers on subfloors

- Extended acclimation periods prior to nailing

Combining these methods with certified installation practices ensures minimal wood movement and prevents finish failures.

What Other Factors Should Influence Your Flooring Choice Beyond Price?

Making a well-rounded decision involves considering aesthetics, sustainability, and functional suitability alongside cost.

How Do Aesthetic Trends Like Wide Planks and Natural Tones Affect Flooring Costs?

Wide-plank boards (5–8 inches) create a sense of spaciousness but typically add $1.00–$2.50 per square foot to the cost due to lower manufacturing yields. Natural, low-gloss, and matte finishes are currently trending, and these may require premium oil-based or UV-cured coatings, adding approximately $0.50–$1.00 per square foot in material costs. Intricate patterned layouts, such as herringbone or chevron, can potentially double the labor costs for installation.

Trend-driven customization can significantly enhance visual appeal but requires careful budget planning.

What Are the Sustainability and Eco-Friendly Options in Hardwood Flooring?

Environmentally conscious homeowners have several excellent options:

- FSC-certified solid or engineered hardwood

- Flooring made from reclaimed or salvaged wood

- Finishing systems that utilize low-VOC, water-based products

- Engineered options using rapidly renewable species like bamboo or eucalyptus, topped with real wood veneers

These eco-friendly choices may come with a 10–25% premium but align with green building certifications and prioritize indoor air quality.

How Does Flooring Suitability Vary by Installation Location (Basements, Radiant Heat)?

Specific considerations for different installation locations include:

- Basements – Engineered hardwood installed over a moisture barrier is recommended

- Radiant heat systems – Engineered flooring specifically rated for heat transfer should be used

- Bathrooms/kitchens – Solid hardwood can be used with specialized sealants and adequate ventilation

- High-traffic areas – Harder wood species like hickory or wide-plank solid wood are ideal

Matching the flooring type to the specific function of the room is essential to prevent premature wear and finish failure.

Why Choose Premier Custom Hardwood Flooring for Your Solid or Engineered Hardwood Needs in Chicago?

Our professional expertise and deep understanding of local conditions ensure superior results and complete customer satisfaction.

What Local Expertise Does Premier Offer for Hardwood Flooring in the Northwest Suburbs?

Premier Custom Hardwood Flooring brings decades of specialized experience in tailoring installations and refinishing projects to the unique seasonal humidity and temperature cycles of the Chicago area. Our skilled technicians conduct thorough moisture mapping, meticulous subfloor preparation, and precise acclimation processes, guaranteeing that each hardwood plank remains stable and beautiful for years to come. In-field adjustments are made to minimize callbacks and protect your investment.

Our extensive local knowledge guides the selection of appropriate wood species, finish types, and installation methods that are best suited to thrive in your home environment.

How Does Certification Ensure Quality Installation and Refinishing?

Our team is committed to upholding the highest industry best practices and engaging in continuous professional development. Our professionals meticulously follow detailed guidelines for acclimation, moisture control, and dustless sanding, ensuring installations that meet warranty requirements and refinishing that achieves flawless results. This commitment underscores our dedication to exceptional craftsmanship and ongoing technical excellence.

This recognized authority validates our commitment to reliability and superior performance.

How Can You Get a Free Estimate and Consultation?

To request a complimentary, no-obligation estimate, simply schedule an on-site evaluation of your subfloor conditions, room layout, and design preferences. We provide clear, itemized proposals that detail material, labor, and finish options, empowering you to compare solid and engineered hardwood scenarios effectively. Our consultative approach ensures all your questions are answered and that your choices align perfectly with your budget and home design aspirations.

Request a Free Quote Today to explore the most advantageous hardwood flooring investment for your Chicago home.

Solid hardwood offers superior longevity and multiple refinishing opportunities, though it comes with a higher initial investment in materials and installation. Engineered hardwood provides a more accessible entry price point, enhanced moisture stability, and greater flexibility in modern styling. Both options have the potential to significantly enhance your home’s value and aesthetic appeal when carefully matched to the installation location, budget, and your specific lifestyle. With Premier Custom Hardwood Flooring’s deep local expertise, unwavering commitment to certified standards, and complimentary consultations, Chicago homeowners gain invaluable clarity on price variations and the confidence to select the ideal wood flooring for generations of enjoyment.